Digital monitoring and control systems have become standard in modern yachts and ships, enabling centralized management of key onboard functions. These systems are typically installed on top of the vessel’s core control infrastructure and can greatly improve systems monitoring and functionality by adding automation and data collection functions. At OSA Solutions, we have deep expertise working with these platforms, including advanced systems from manufacturers like Naviop and Boening.

What Are Digital Ship Monitoring and Control Systems?

Ship monitoring and control systems are electronic architectures that collect, process, and display data from various onboard subsystems such as:

- Engines and generators

- Fuel and water tanks

- Battery banks and shore power

- Fire detection and bilge systems

- HVAC, lighting, and security

- Navigation equipment and alarms

These systems consolidate everything into a central touchscreen interface or multiple redundant displays, allowing crew or operators to make informed decisions and take immediate action when necessary.

Common Components and Architecture

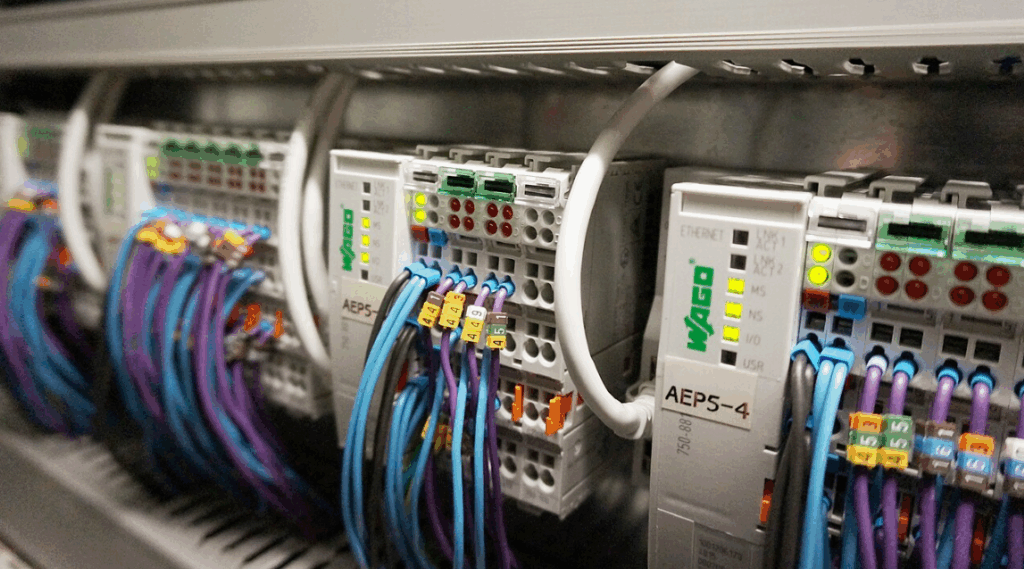

A modern ship monitoring and control system is composed of a network of hardware and software elements working together to collect, transmit, and process data in real time. These systems are usually designed around a distributed architecture, which increases flexibility, scalability, and redundancy.

Key components typically include:

- Remote I/O Modules – These units interface with sensors and actuators across the vessel, collecting analog and digital inputs such as tank levels, temperatures, switch statuses, and relays. They’re often mounted close to the monitored equipment to minimize wiring runs.

- PLC-Based or Embedded Controllers – At the heart of the system is a programmable logic controller (PLC) or industrial-grade embedded system that processes all data, runs control logic, manages alarms, and communicates with displays or external systems.

- Data Communication Networks – Protocols like CANbus, NMEA 2000, Modbus TCP/RTU, and Ethernet are used to link modules, controllers, and operator stations. Some systems also integrate proprietary protocols depending on the manufacturer.

- Human-Machine Interfaces (HMI) – Touchscreens or multifunction displays provide intuitive control and visualization. These can be fully custom, multilingual, and designed to operate in harsh marine environments with sunlight-readable screens and IP-rated enclosures.

- Alarm and Safety Integration – Monitoring systems often integrate with bilge alarms, fire suppression systems, genset alarms, and critical engine parameters to ensure immediate feedback and logging in case of faults.

- Remote Access and Logging – Some systems support cloud connectivity, allowing shore-side monitoring, remote diagnostics, firmware updates, and detailed operational logs for maintenance planning.

In many cases, the system design is modular and distributed, meaning sensors and actuators are spread across the vessel and communicate back to a central logic processor or networked controllers.

Troubleshooting and Custom Solutions

In our work across South Florida, we frequently assist vessels with:

- Failing or outdated monitoring systems

- Network communication issues

- Inconsistent sensor data

- Faulty logic controllers or I/O modules

- Incomplete documentation or abandoned projects

Our technical expertise allows us to reverse engineer undocumented systems, source or fabricate replacements, and implement custom control logic when off-the-shelf solutions don’t fit.

Conclusion

Ship monitoring and control systems are critical to modern vessel operations. As these systems grow in complexity, the need for technically capable marine electrical experts becomes essential. Whether you’re operating a high-end yacht or a commercial vessel, OSA Solutions delivers precision, reliability, and adaptability in every project involving onboard automation and monitoring.